1. Overview: A rotary cooler is a large mechanical device that dissipates heat and water from dried materials. This machine is one of the key equipment in the fertilizer industry, used to cool the formed fertilizer particles. As the particle temperature decreases, the moisture content also decreases, and the particle strength increases accordingly. The machine continuously draws ambient temperature air from the tail of the cooling machine above the head through a fan connected to the air outlet position of the machine head. As the machine body rotates, the lifting plate inside continuously lifts and throws the formed particles, allowing the material to fully contact the cold air and form heat exchange, thereby achieving uniform cooling.

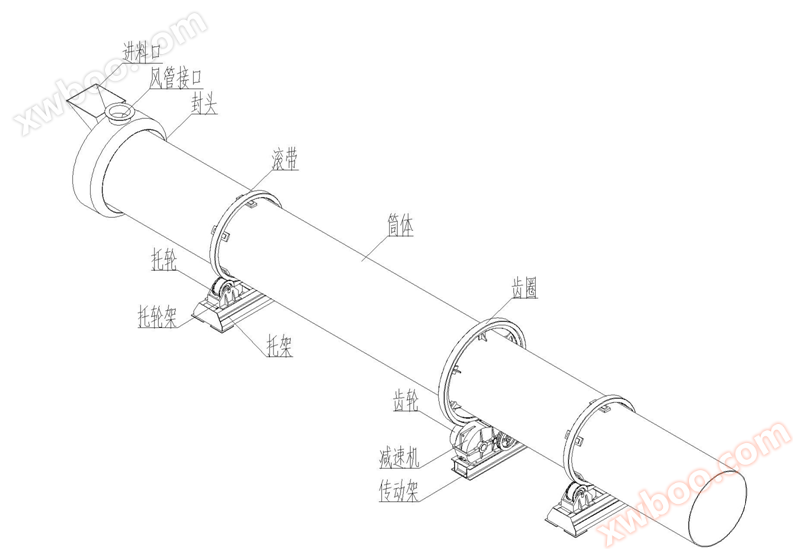

2. Structure: The whole machine can be divided into four main parts:

a. Bracket section: The bracket section includes a front bracket and a rear bracket, which are fixed to the corresponding foundation and used to support the cylinder for positioning and rotation. The front and rear brackets are composed of brackets, roller frames, and rollers. During installation, the height and angle of the equipment can be adjusted by adjusting the distance between the two wheels on the front and rear brackets.

b. Transmission part: The transmission part provides the necessary power for the normal operation of the entire coating machine. Its components include a transmission frame, a motor, a triangular tape transmission mechanism, a reducer, and a gear transmission mechanism, among which the reducer and the gear are connected and driven by direct coupling or coupling according to the load size.

c. Cylinder: The cylinder is the working part of the entire cooling machine. It has rolling belts for support and gear rings for transmission on the outside, and material lifting plates welded inside are distributed in rows. During the operation of the cooling machine, materials are continuously lifted and thrown to form heat exchange for cooling purposes.

d. Head seal, tail seal, and air duct: This part constitutes the cold air circulation and dust removal system required for the operation of the cooling machine. The sealing between the head and the body joint is good, which continuously reduces the temperature of the particle surface with cold air, achieving the goal of uniform cooling of the particles. When the operator needs to enter the interior of the cylinder for operation, please enter from the tail of the machine while the machine is stopped.

3. Characteristics

The rotary cooling machine developed by our company has the following characteristics:

a. Small investment, quick returns, and high cost-effectiveness.

b. Small power, low energy consumption, stable operation, and easy maintenance.

c. The distribution and angle design of the lifting plate are reasonable, and the performance is reliable, resulting in high heat exchange efficiency, uniform cooling, and fewer material cleaning times.

1、 Main technical parameters

There are multiple models of this series of rotary cooling machines, which can be selected according to the user's production needs or customized, with a wide range of choices. The main technical parameters are shown in the table below:

model |

diameter (mm)

|

length (mm)

|

after installation Overall dimensions(mm)

|

speed (r/min)

|

electric motor model

|

power (kw)

|

HG0880 | 800 | 8000 | 9000×1700×2400 | 6 | Y132S-4 | 5.5 |

HG10100 | 1000 | 10000 | 11000×1600×2700 | 5 | Y132M-4 | 7.5 |

HG12120 | 1200 | 12000 | 13000×2900×3000 | 4.5 | Y132M-4 | 7.5 |

HG15150 | 1500 | 15000 | 16500×3400×3500 | 4.5 | Y160L-4 | 15 |

HG18180 | 1800 | 18000 | 19600×3300×4000 | 4.5 | Y225M-6 | 30 |

HG20200 | 2000 | 20000 | 21600×3650×4400 | 4.3 | Y250M-6 | 37 |

HG22220 | 2200 | 22000 | 23800×3800×4800 | 4 | Y250M-6 | 37 |

HG24240 | 2400 | 24000 | 26000×4000×5200 | 4 | Y280S-6 | 45 |

2、 Installation, debugging, and maintenance

1. Installation:

After the machine arrives at the factory, it is placed on the corresponding concrete foundation according to the process flow, with a general inclination angle of 2.3 degrees (adjustable according to user needs). The machine bracket and transmission frame are placed on the concrete pier, adjusted in position, and welded together with the embedded parts. If wedge-shaped pads need to be inserted between each base and foundation, their thickness should not exceed 35mm.

a. Before installing the equipment, the foundation should be prepared and the equipment can only be installed after the concrete has solidified.

b. Adjust the height of each base with wedge-shaped pads as needed to maintain the desired tilt angle of the machine.

c. Adjust the roller frame to the appropriate position, place the cylinder on the roller, and adjust the spacing between each component.

d. Install the transmission part of the cooling machine and adjust the meshing clearance between the gear and the ring gear.

2. Debugging:

a. During the test drive, pay attention to the direction of rotation of the machine body. The small gear and large gear ring should rotate backwards. If the direction of rotation of the machine body is incorrect, adjust the phase sequence.

b. The temperature of each bearing should rise steadily, and the bearing temperature should not exceed 50 ℃ during long-term use.

c. The noise of gears should be uniform and not fluctuate high or low.

d. After the test drive is completed, observe that there is no serious wear on the roller, idler, gear, ring gear, etc.

3. Maintenance and upkeep:

a. Before using the reducer, lubricating oil must be added. The lubricating oil is generally HJ40-50 mechanical oil, or HL20-30 gear oil can be used. The oil level height of the lubricating oil should be within the range indicated by the circular oil mark on the machine base. After the first refueling operation for 100 hours, the oil should be replaced with new oil, and then replaced every four months. When changing the oil, it should be cleaned thoroughly.

b. Lubricate the bearings once every shift with a type of 3 calcium based grease lubricating oil, with a filling amount of 1/3~1/2, and regularly replace with new lubricating oil. The bearings should be cleaned during replacement.

c. Dry butter should be applied to the surface joints of gears, ring gears, rollers, and pulleys.

4. Fragile parts

a. Triangle belt b. Bearing c. Coupling pin

3、 Usage and Operation

1. Power on:

a. Apply dry butter to the gears and rollers, and inject an appropriate amount of butter or gear oil into the bearing seat and reducer.

c. Turn on the dust removal fan before starting the equipment for transporting materials, and avoid starting the cooling cylinder with materials.

2. Parking:

Stop the equipment of each process before the cooling machine in sequence, wait for the materials inside the cooling machine to be completely discharged, and then stop the equipment of each subsequent process in sequence later.

3. Precautions:

a. Personnel are prohibited from passing under the cooling machine during operation.

b. During the operation of the cooling machine, internal inspection and repair are prohibited.

c. Do not touch the motor and wires without wearing insulated gloves.

d. Without a complete grounding wire, it is prohibited to start the cooling machine. If current is found on the equipment, it should be stopped immediately until the grounding wire is repaired.

4、 Common faults and troubleshooting methods

Fault phenomenon | 故障原因 | exclusion method |

Rolling belt sliding | The concave joint of the rolling belt is not clamped on the side | Clamp the side of the roller belt and the concave joint |

There is no clamping between the roller belt and the concave joint in the radial direction | Use shims or wedges to clamp the roller belt and concave joint, but it is important to note that excessive clamping can lead to accidents, while uneven tightening can cause the machine to jump and vibrate |

Misalignment of the body | Wheel wear and tear | Repair or replace the idler according to the degree of wear and tear |

Wheel wear and tear | Repair, move or replace the gear wheel according to the degree of wear and tear |

Gear misalignment | Small gear wear | Reverse the installation of the small gear. If both sides are worn, a new gear needs to be replaced |

The connection between the large gear and the cylinder is damaged | Proper handling shall be made when necessary for the calibration and connection |

Cylinder vibration | The connection between the supporting wheel device and the base is damaged | Adjust the connection and tighten the nut to ensure that the supporting wheel is in the correct position |

Wear on the side of the roller belt | Turn the side of the rolling belt according to the degree of wear or replace it with a new rolling belt |